Description

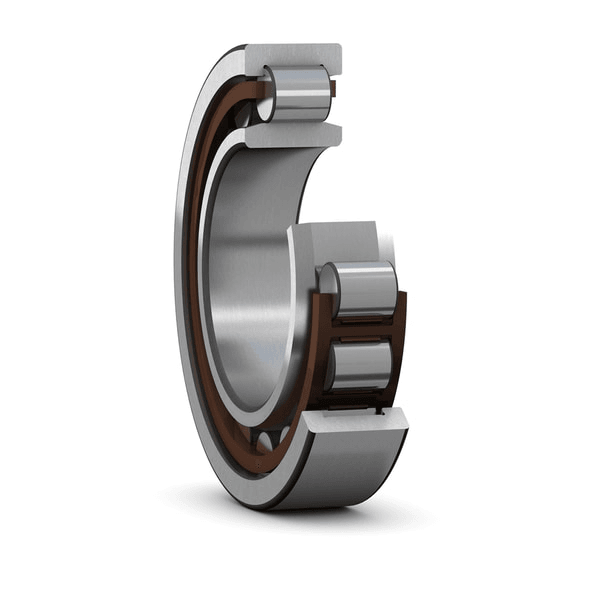

| Bore type | Cylindrical |

Dimensions

| d | 900 mm | Bore diameter |

|---|---|---|

| tΔdmp | -0.1 – 0.0 mm | Deviation limits of mid-range bore diameter |

| D | 1 280 mm | Outside diameter |

| tΔDmp | -0.16 – 0.0 mm | Deviation limits of mid-range outside diameter |

| B | 375 mm | Width |

| tΔBs | -1.0 – 0.0 mm | Deviation limits of ring width |

| d2 | ≈ 1 024 mm | Shoulder diameter of inner ring |

| D1 | ≈ 1 164 mm | Shoulder/recess diameter of outer ring |

| b | 69.1 mm | Width of lubrication groove |

| K | 15 mm | Diameter of lubrication hole |

| r1,2 | min. 7.5 mm | Chamfer dimension |

| Normal | ISO tolerance class for dimensions |

Abutment dimensions

| da | min. 928 mm | Diameter of shaft abutment |

|---|---|---|

| Da | max. 1 252 mm | Diameter of housing abutment |

| ra | max. 6 mm | Radius of fillet |

Calculation data

| NR performance class | NR Explorer | |

| Basic dynamic load rating | C | 16 215 kN |

| Basic static load rating | C0 | 34 000 kN |

| Fatigue load limit | Pu | 2 040 kN |

| Reference speed | 20 r/min | |

| Limiting speed | 40 r/min | |

| Limiting value | e | 0.27 |

| Calculation factor | Y1 | 2.5 |

| Calculation factor | Y2 | 3.7 |

| Calculation factor | Y0 | 2.5 |

Tolerances of run-out

| Range of section height at inner ring of assembled bearing | tKia | 90 µm |

|---|---|---|

| Range of section height at outer ring of assembled bearing | tKea | 190 µm |

| ISO tolerance class for geoal tolerances | Normal |

Radial internal clearance

| Minimum initial clearance | 430 µm |

| Maximum initial clearance | 650 µm |

Tolerances and clearances

General bearing specifications

- Tolerances: Normal, P6, P5,

tapered bore 1:12, tapered bore 1:30 - Radial internal clearance: cylindrical bore, tapered bore

Bearing interfaces

- Seat tolerances for standard conditions

- Tolerances and resultant fit

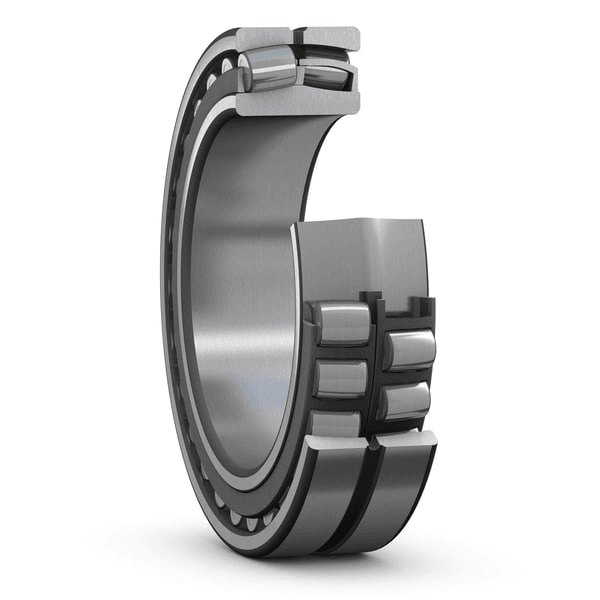

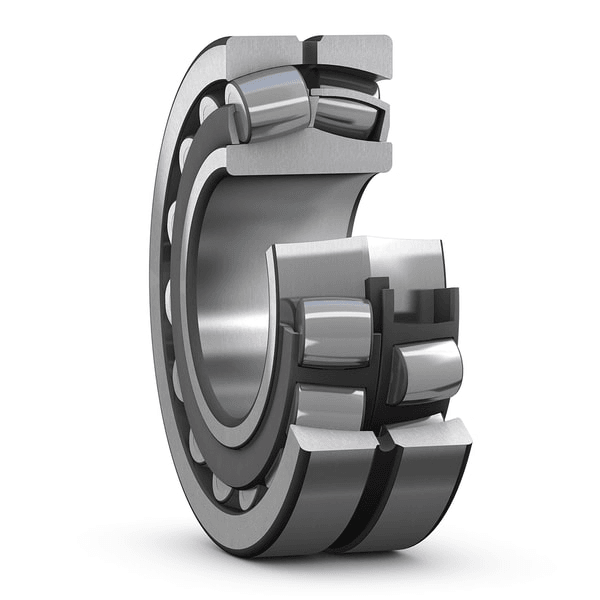

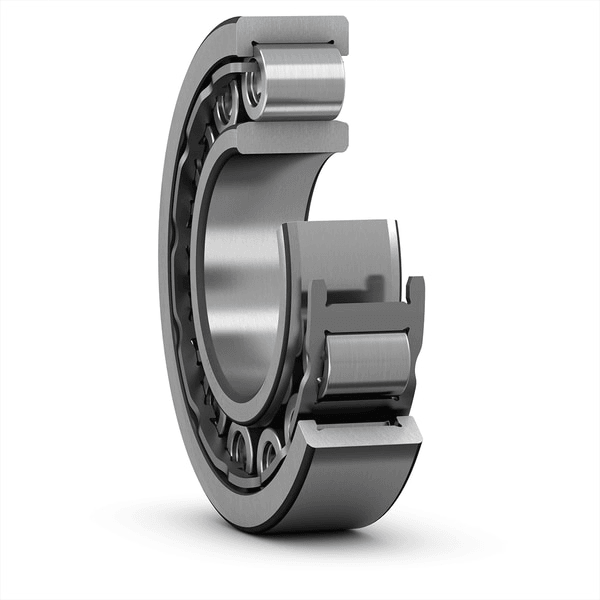

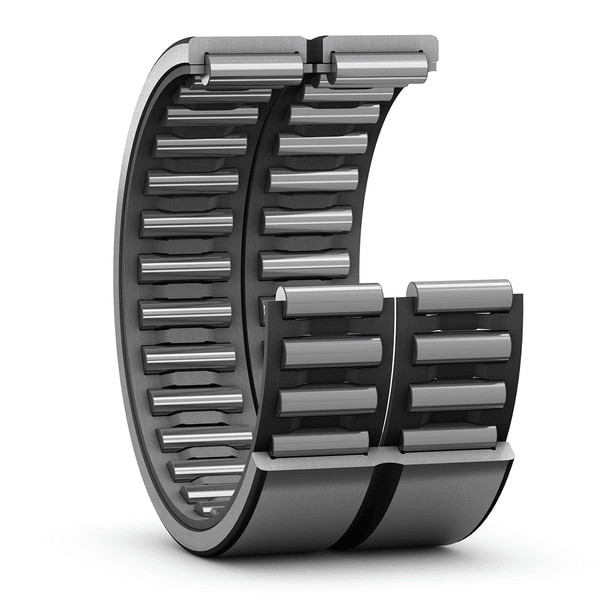

Spherical roller bearing for wind turbine main shafts are optimized to handle the varying direction and high thrust loads of wind energy applications, allowing to perform more reliably under typical operating conditions. A modified inner geometry with super-finished functional surfaces makes this possible. Using a one-piece roller-guided cast-iron cage and an enlarged lubrication groove increases robustness.

- Improved performance under wind operating conditions

- Accommodate misalignment

- Up to twice the fatigue life

- Increased robustness for both radial and axial load conditions

- Improved lubrication